Born in the city of Otaru, Hokkaido in 1921,

we kept moving forward till this day

From metal cans to containers in general

Expansion of production bases and out to the global market

We have grown into a total packaging manufacturer,

encompassing not only container manufacture

but filling and machinery production businesses as well

It was a journey filled with challenges

Inheriting the DNA and manufacturing spirit of our founders,

we have come thus far

Our challenges will continue

Hoping that we can look back on our footsteps one day

and say, “How far we have reached,” “What a high mountain we have climbed”

Today again we will make a step forward,

with a pioneering spirit at heart and backed by a strong history

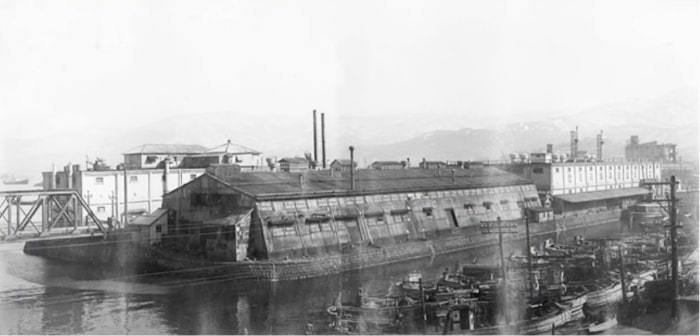

1921

Otaru Factory at the

time of foundation

Founded in Otaru;

The founder was a former

crew of Hojoh ship

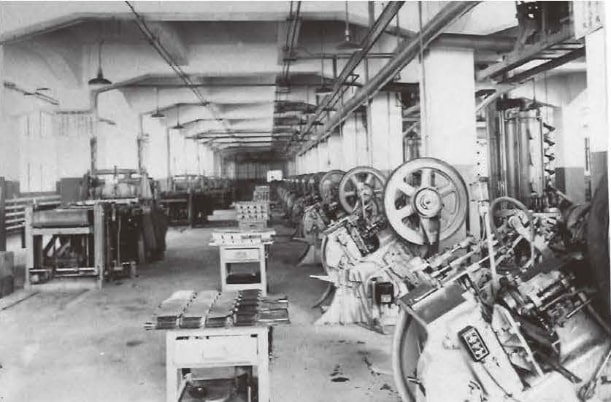

Our first business started

from manufacturing

empty cans for marine products.

Expanding business to

agricultural products and dairy

products cans

1973

Began manufacturing beverage cans

1989

Began manufacturing

PET bottles

1996

Foundation of

NIHON CANPACK MALAYSIA

SDN.BDH.

1997

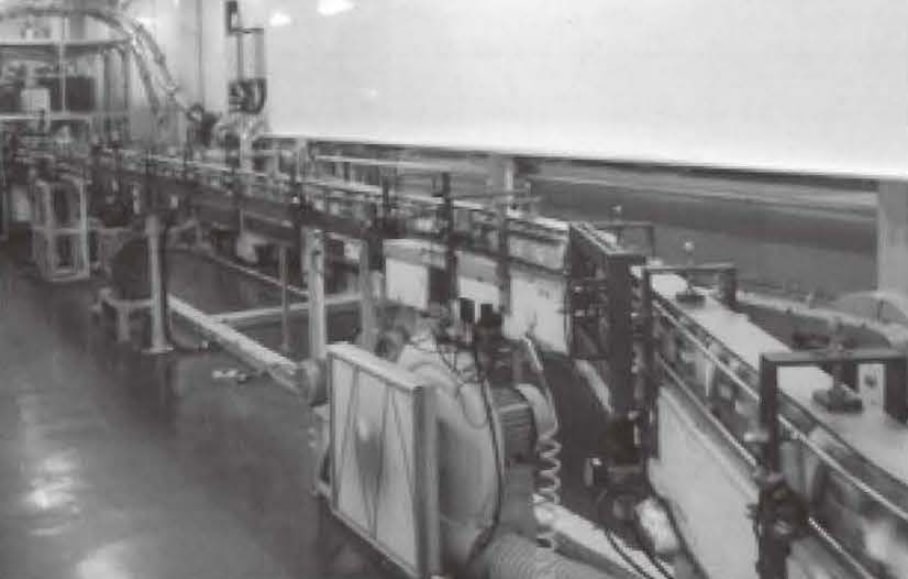

Completion of world’s fastest

“1000 cans per minute”

manufacturing line

2007

Foundation of

NIHON CANPACK(VIETNAM)

CO.,LTD

2011

Foundation of

PT. HOKKAN INDONESIA

2018

Foundation of

PT. HOKKAN DELTAPACK INDUSTRI

GROUP

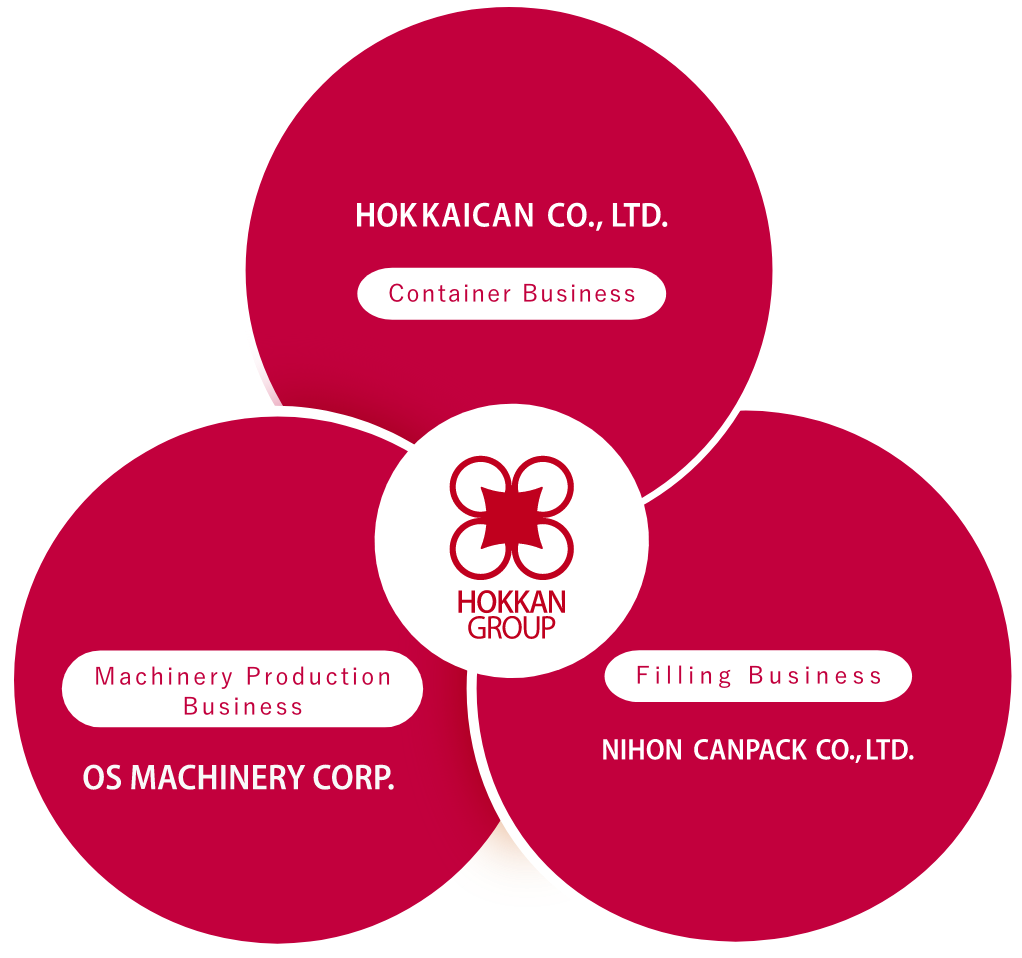

The history of

HOKKAN Group

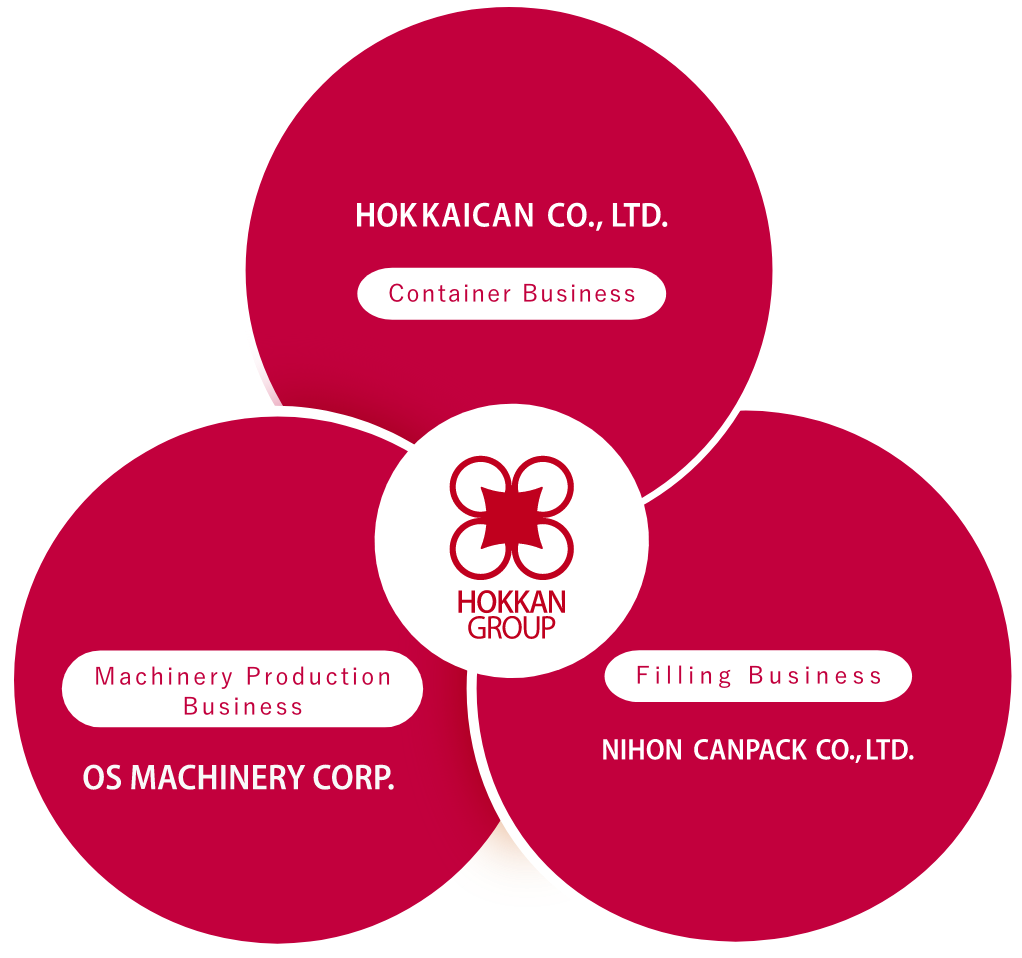

HOKKAN Group

In 1921 HOKKAN Group started by producing canned food, a new form of food in Japan, and went on to manufacture beverage cans, PET bottles, and into business fields other than food and beverages. We have also expanded to overseas markets. For over 100 years we have continuously responded to people’s needs in line with the times but maintained the same passion and sincere attitude to manufacturing since our early days.

HOKKAN Group will continue to embark on new challenges as a pioneer of the times.

HISTORY

A century-long history since the founding

It all started

from a small can

of crabmeat

It all started from a small can of crabmeat

Our roots, HOKKAI CAN WAREHOUSE was born in the City of Otaru, Hokkaido in 1921.

In this land blessed with an abundance of seafood from the northern sea, the first products we made were canned salmon and crabmeat, which were still quite rare at that time.

This new technique of canning food provided a good way to preserve crabmeat when crabs used to be so bountiful that they were often thrown away. Canned crab soon became a popular export product.

Garnering popularity among not only Japanese consumers but in Western countries, canned food grew to be a star industry of the times.

We continued to launch other types of canned food such as asparagus, sweet corn, milk and butter, using the blessings of the land of Hokkaido and became a driving force to spread a new food culture.

BACKGROUND

The process until a

canned or bottled

beverage is

produced

canned or bottled

beverage is

produced

You may often purchase canned or bottled drinks, but have you ever thought about the process till they are manufactured?

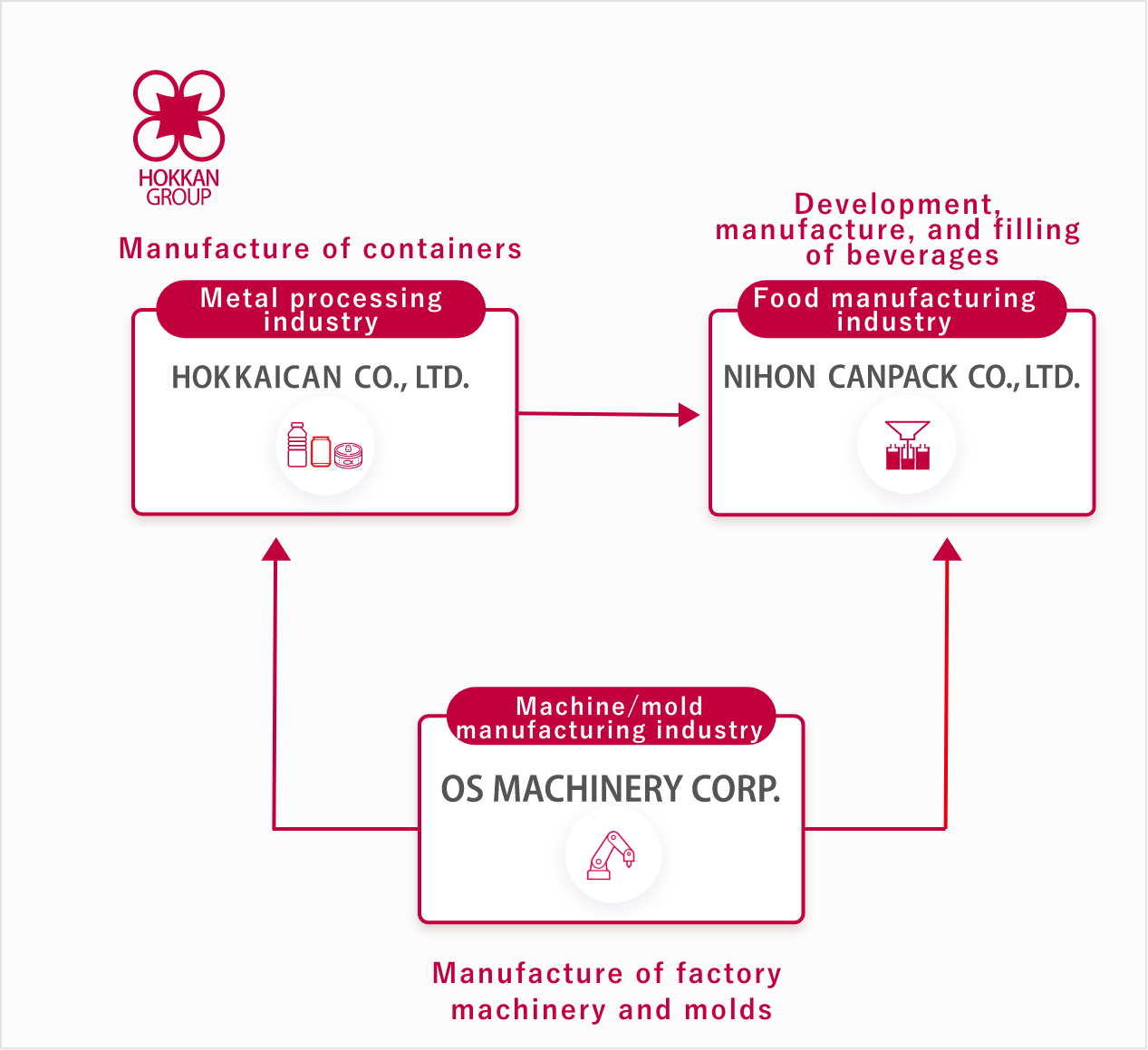

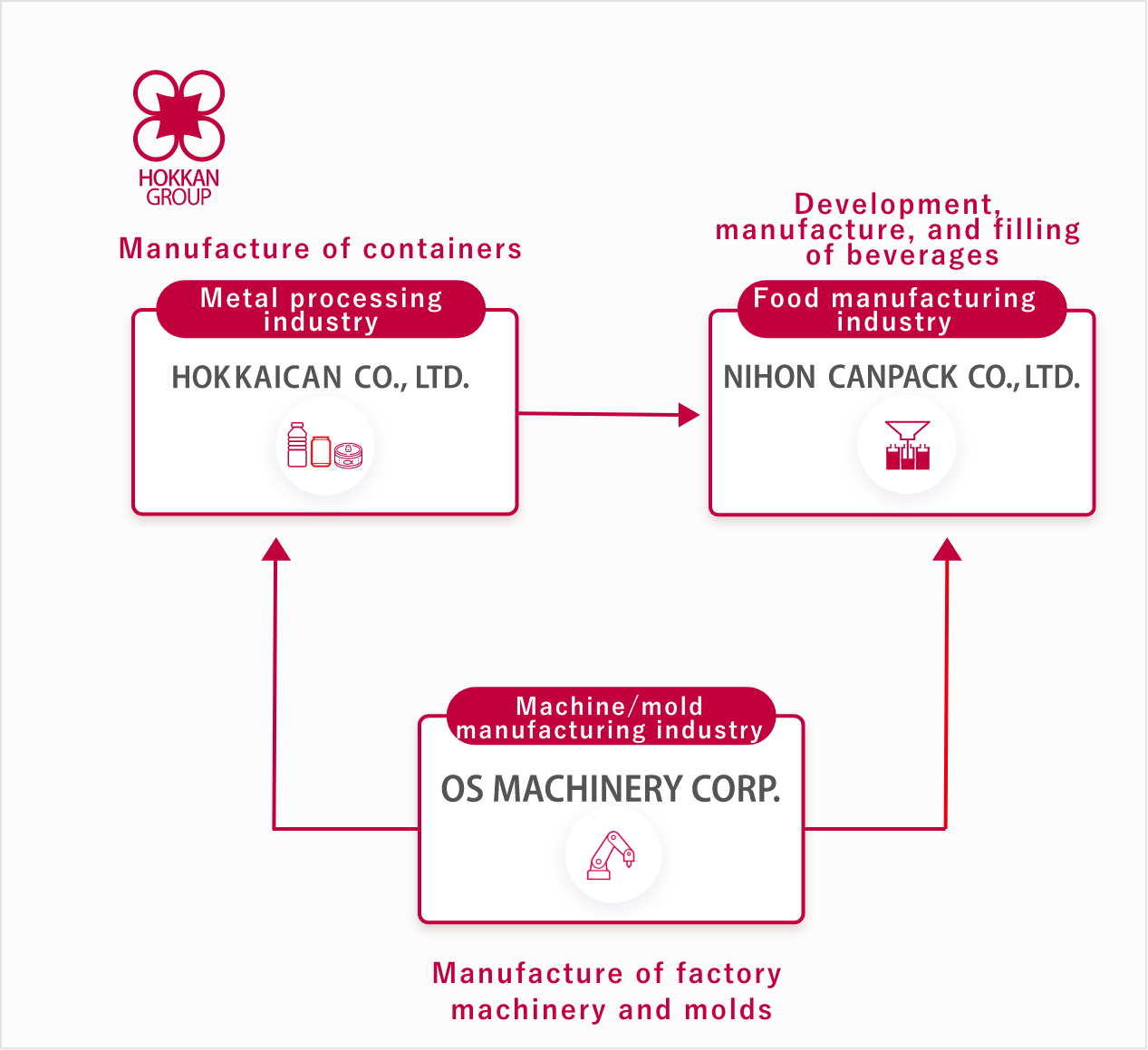

Among the various products HOKKAN Group manufactures, bottled and canned beverages best showcase the collective strengths of the Group.

Beverage products are comprised of the container (can, PET bottle, etc.) and the content (tea, fruit juice, etc.). HOKKAN Group can undertake almost all of the processes to produce such products.

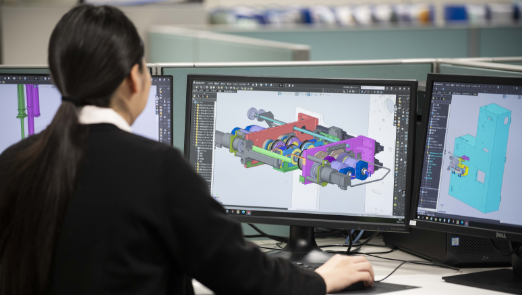

While HOKKAI CAN manufactures the container, NIHON CANPACK develops and manufactures the beverage to fill that container and performs the filling process as well. OS MACHINERY produces the factory machines and molds necessary to make and fill the containers.

Let us show you the back stages of beverage production with world’s top quality and speed, realized through collaboration among Group companies.

OCCUPATION

Job types

development, and

technology

support

machine, and

information

systems engineering

manufacture cans

Identify new technologies and social trends to determine development strategies

Collect information on customer needs and prior art from open data sources, meetings

with customer, market survey, past cases, patent information, and other information

sources

resins, and additives and fundamental technology development such as improvement of

processability

Design the container using 3DCAD

Use such techniques as Finite Element Method and 3D printing as necessary

products and technologies

and usability of products

Propose such techniques and materials to customers to help realize their needs and

requests

Reduce environmental impact by developing containers with thinner materials, reducing

material use, and other means

development

dimensions and performance

food and beverages

support product development and design for leading beverage manufacturers

Support new customer development of overseas Group companies through recipe

development, sales support, etc.

Jointly develop beverage products with local municipalities and chambers of commerce

and industries as part of our CSR activities

Responsibilities related to food development are: to develop and test produce canned

food mainly from seafood and agricultural products

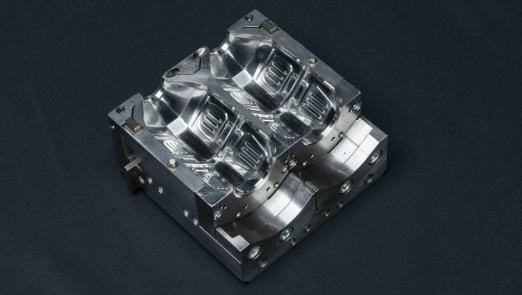

technology development

containers under development and establish the molding process technology for mass production of new containers

development

Issue standard documents, standardize manufacturing processes and methods, and be on

site when starting production

Respond to customer requests for research of manufacturing processes, and improve yield and production efficiency of existing products

impact of containers

produced or developed and devise products and mass production processes that would

reduce environmental impact

seaming technology

filling equipment

sterilization technology

positions and how to apply

GLOBAL GROUP

Overseas branches

to a country of canned coffee

Taking advantage of such characteristics, NIHON CANPACK VIETNAM was established in 2007 as the first contract filler in Vietnam with an aim to spread canned coffee culture.

The company offers high-quality filling services and products including canned coffee, drinks with solid content, and other canned beverages utilizing Japanese manufacturing technology and know-how. It is also committed to research and development for driving quality improvement.

Dugong Province,Vietnam

The No. 1 supplier of plastic cups

It will continue to meet the growing beverage demand in rapidly developing Indonesia and other parts of Southeast Asia.

positions and how to apply